Environmental Sustainability Management

Environmental Policy and Guidelines

The Company realizes that steel industry plays a role in national development and consumes natural resources in production process. Thus, the Company constantly prioritized the environmental management by adhering to business operation ethics and philosophy. Occupational health, safety and environment policy and environmental work plan are included in business operation.

The Safety, Environment and Plant Integrity Management Office is a main driving force on environmental management which jointly works with other production units in the plant site. The environmental managers, supervisors, and operators in charge of water, air pollution and waste control systems have been fully appointed pursuant to the laws. Implementation in accordance with the laws relevant to environmental matters has been strictly complied, including the study and preparation of environmental impact assessment report, the compliance with the preventive and corrective measures to minimize the environmental impact from steel manufacturing, the measures to monitor quality of the environment, ISO 14001 Environmental Management System, ISO 45001: Occupational Health and Safety Management standard system.

For the operations outside the plant, the Company jointly cooperated with other companies in Sahaviriya Steel Group in Bangsaphan District to promote and cultivate the environmental awareness, and the collaboration between the communities and the plant through various activities throughout the year

Environmental Operating Results

Energy Management

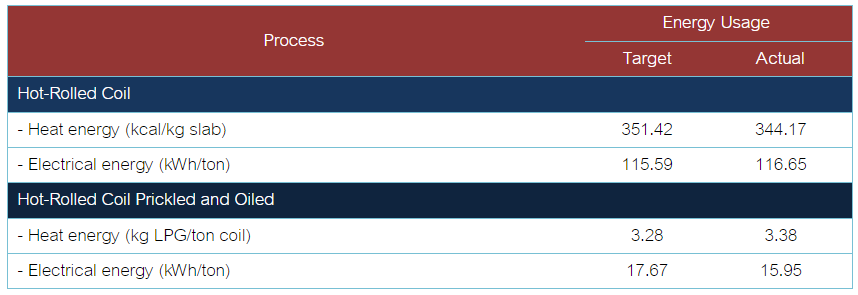

The Company controlled and optimized usage of energy in the organization. The energy management working group acts as a center to manage energy in collaboration with various departments within the organization as cross functional team by regularly implementing joint energy saving measures, both concerning with direct production process, such as steel furnace system, motor driving systems, and concerning with production support systems, such as wastewater treatment systems, compressed air system, lighting system. The Company has implemented and applied the international standard of Energy Management System, ISO 50001: 2018 within the organization in order to improve energy performance, reduce environmental impacts, reduce energy costs and fostering concrete participation on energy saving.

Apart from energy conservation within the organization, the Company also put emphasis on cooperating with the energy promotion projects of the public sectors on continuous basis, for instance, attending in the seminar on the energy conservation supervisory project in accordance with the laws on factory control, as well as placed emphasis on personnel development training by supporting the budget for personnel development continually. The Company also encouraged for employee engagement on energy conservation activities, which resulted in participatory energy saving throughout the organization.

Energy consumption rate of SSI Bangsaphan Steelworks in 2022

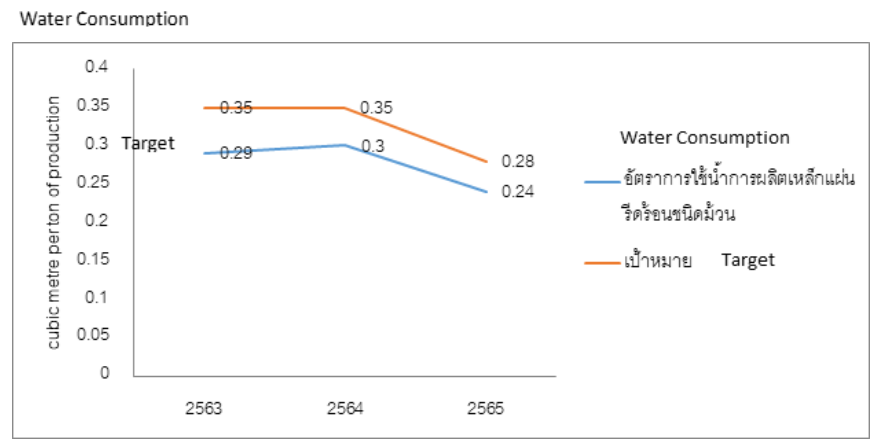

Water Management

SSI Bangsaphan Steelworks uses raw water from Bangsaphan canal, a huge surface water source located 13.5 km. far from the plant. Water is pumped into 2.4 million cubic meters water reservoir. However, SSI will not pump water from Bangsaphan Weir during dry season when water level in the weir is below 2.2 meters. The plant is also designed to recycle water in the HRC production.

Such water consumption management within the plant allows the Company to keep on production without having water shortage problem as water is a common resource shared with the community and local agricultural sector. Throughout year 2022, the Company still strictly adhered to the set measures.

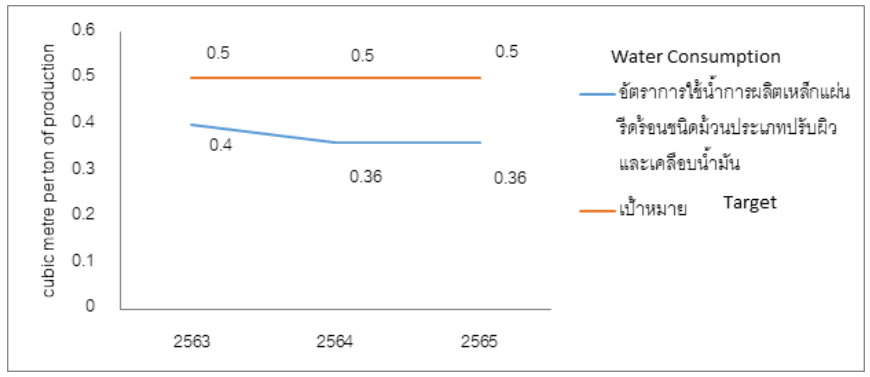

For the treatment of wastewater, SSI has installed chemical water treatment system to reduce levels of wastewater generated in the HRC-pickled and oiled production line, installed sedimentation tanks, sand filters and grease trap tanks in the HRC production line, and equipped with biological treatment system for wastewater from consumption within the plant. The quality of water in all systems has been constantly tested by the officials and verified by the external certification body authorized by the government agencies. The treated water is recycled and some of which is used to water the plants, with zero discharge outside the plant.

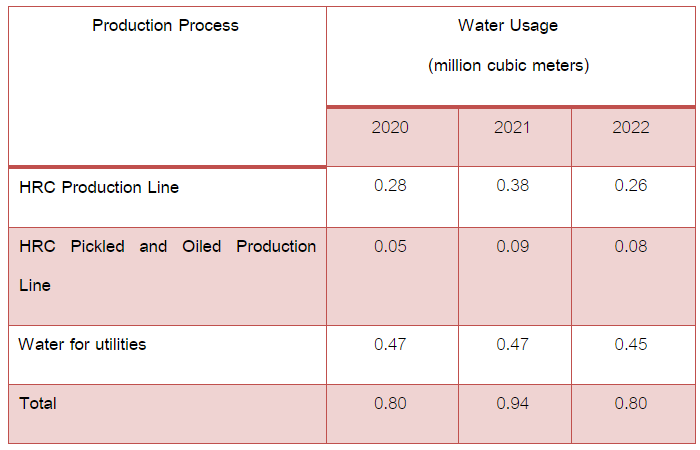

In 2022, total water consumption in SSI Bangsaphan Steelworks was 0.8 million cubic meters, consisting of

1) HRC production line at 0.26 million cubic meters;

2) HRC pickled and oiled production line at 0.08 million cubic meters,

and 3) Water for utilities at 0.45 million cubic meters.

Control of Water Quality

Though, the Company’s water treatment system has been designed as zero discharge, but the Company still inspected quality of water, both within and outside the plant, as follows:

- Inspect quality of treated water at 4 stations by the third-party agency approved by the Industrial Works Department. Results obtained were better than the standard value of effluent as per specified in the Notification of the Ministry of Industry B.E. 2560.

- Inspect quality of subsurface water at 9 stations on semi-annual basis by the third-party agency approved by the Industrial Works Department. Currently, Thailand does not have the relevant standards on subsurface water, so the Company monitored any possible change but from analysis conducted during the past years, no significant change was detected.

- Inspect quality of surface water in public water sources at 3 stations, Klong Tha Kham, Klong Mae Rumpueng’ s headwaters and end of Klong Mae Rumpueng, on semi-annual basis by the third party agency approved by the Industrial Works Department to ensure that business operations of the Company will not have any impact to the environment.

Chemical Usage

Various chemicals were used in the water production system in the hot-rolled coil production line and hot-rolled coil pickled and oiled production lines. During the past year, the Company did not use new chemical in the plant and chemical usage rate in the processes did not have tendency to increase. In addition, inspection results pursuant to the ISO 14001 and ISO 45001 standards on chemical control and management in the plant were under the operating standards. However, there were some recommendations, but the relevant parties have already prepared the plan for such improvement.

Pollution and Waste Management

The Company is committed to reduce quantity of waste at source by applying the 3Rs Principle – Reduce, Reuse and Recycle. Waste in the production process and in the office have been taken into reduction, reuse and recycle projects, for instance, reduction of contamination of used oil from repeated use, compilation of wasted food from consumption by the staff to process for fermented bio-extract to distribute to the staff. The Company also selected waste disposal methods with minimal environmental impact, for instance, the Company used services of a well-known waste processor with expertise and certification issued by the authorized government agency for proper waste disposal standard as required by laws which has been accepted by many service users. In addition, for industrial waste management, the Company employed industrial waste pollution controller, to ensure that the operation has been performed correctly and in compliance with the laws.

Due to determination on effective waste and pollution management, the Company received 3 awards from the project on enhancement of unlawful disposal of industrial waste management by applying 3Rs and KAIZEN principles arranged by the Department of Industrial Works, Ministry of Industry

- 3Rs (3Rs Award)

- Zero Waste Achievement Award

- 3R+ Award, Bronze Medal

Apart from receiving those awards, the Company also participated in the “Project to Promote and Develop the Recycled Technology for Development of Wastes to Renewable Sources in Prachuab Khirikhan, Petchburi and Phitsanulok Provinces” arranged by Innovation in Raw Materials and Primary Industries Division, Department of Primary Industries and Mines, Ministry of Industry and Innovative Processing and Recycling of Metals Research Center, School of Metallurgical Engineering, Institute of Engineering, Suranaree University of Technology. From the research under this project, it was found that deteriorated hydrochloric acid from steel manufacturing process can be produced to iron oxide product (hematite – FE203) with purity not less than 97 percent. Hematite is main raw material for production of rustproof paint and it can be commercially expanded, so it is regarded as usage of recycled technology for development of wastes to renewable source, zero waste and to support circular economy for the organization and the community on sustainable basis.

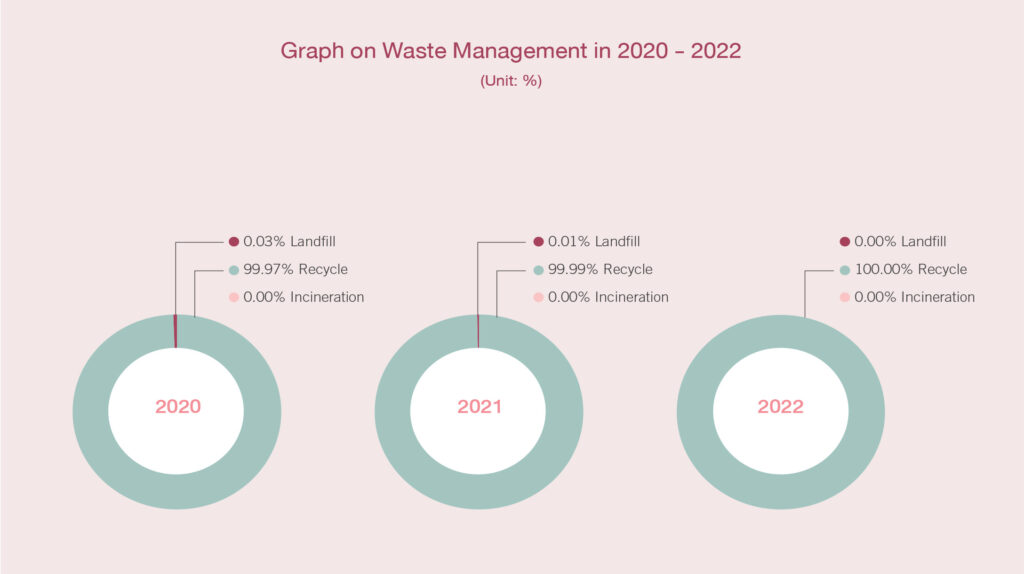

In 2022, total waste generated by the Company amounted to 44,672.364 tons, waste management cost was 15.40 million Baht and sale of 39,258.69 tons of waste amounted to 32.14 million Baht. 100% of waste had been recycled and disposed by zero waste to landfill method which has been approved by the government agency and pursuant to legal requirements.

Air Quality Control

As designed for efficient fuel consumption, SSI Bangsaphan Steelworks has installed computerized combustion system controlling level of sulfur impurity in the fuel not exceeding 2%, resulting in the better level of air ventilation outside the plant than the standard level and requirements specified in the plant’s environmental impact assessment report.

With regards to the hot-rolled coil pickled and oiled production line, acid gas detection systems have been installed both in the production line and in the acid treatment plant for recycling purpose. As a result, level of air ventilation outside the plant was also better than the standard levels and requirements specified in the plant’s environmental impact assessment report.

Various parameters of ambient air quality around the plant have been constantly monitored and inspected throughout the year. In 2022, 5 stations, namely, Baan Tha Kham, Baan Tha Manoa, Baan Klang Aow, Baan Tubmon and Baan Bor Thonglang were monitored. Air quality measured by parameters was as follows:

- Hourly average level of density of sulfur dioxide in the atmosphere

- Hourly average level of density of nitrogen dioxide in the atmosphere

- Hourly average level of total suspended particulate (TSP) in the atmosphere

- Hourly average level of density of hydrogen chloride in the atmosphere

- Hourly average level of particulate matter less than 10 microns (PM10)

- Hourly average level of particulate matter less than 2.5 microns (PM2.5)

Inspection results of air quality pursuant to the above parameters of all stations were much better than the set standard, as same as the results from the previous inspections of all stations and all parameters.

Biodiversity

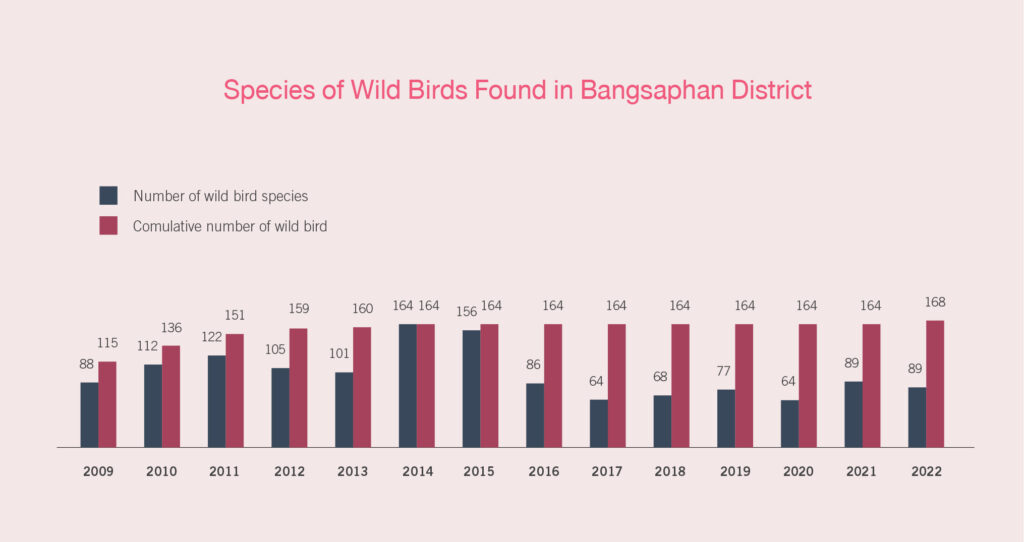

Sahaviriya Steel Industries Public Company Limited (SSI) together with Sahaviriya Steel Group at Bangsaphan have carried out a biodiversity survey project, which is a key indicator of abundance of the eco-system, in the areas surrounding Sahaviriya Steel Group, with details as follows:

The Environmental Monitoring Project on Biological Resources

With commitment to perform the industrial business which can live harmoniously and sustainably with the environment, SSI led by the specialists from the Department of Zoology Faculty of Science, Kasetsart University has conducted the survey on biodiversity (species diversity) for 15 years consecutively (2008-2022) in natural areas near the Sahaviriya Steelworks, such as Samad-Rub-Peek-Nok Forest, Thung Lan Khwai Field, Nok-Ka-Rean Field, Mae Ramphueng Mangrove Forest, and Pa Klang Aow Natural Park.

From the biodiversity survey results in areas surrounding Sahaviriya Steelworks during December 2022, 4 types of animal classification, totaling 120 species of wildlife animals were found. There were 118 species of wildlife animals found from direct sighting, trace evidence and their voices, while 2 species were found from making inquiries (Monocled cobra and dog-faced water snake). They could be classified into 13 species of amphibians, 19 species of reptiles, 80 species of birds and 8 species of mammals. When compared with 2021, 2 more species of mammal were found, i.e., northern slow loris and red spiny rat). Such amount can be classified by each study area located around Sahaviriya Steelworks as follows: (1) 45 species in Thung Don Samran Field; (2) 50 species in Thung Lan Khwai Field; (3) 66 species in Nok-Ka-Rean Field; (4) 56 species in Mae Ramphueng Mangrove Forest; and (5) 41 species in evergreen rain forest plain of Pa Klang Aow Natural Park.

Based on the above information, it can be seen that the forests around Sahaviriya Steelworks in Bangsaphan district are still abundant and remain the habitat for a wide variety of wildlife. There is diversity of various species of wild animals in each study area.

The data reflects that the steel industry is considered environmentally friendly. Besides conducting the biodiversity survey, the Company’s operations were also followed the pollution management standards of the Company and of Sahaviriya Steel Group continually to prevent impact to livelihood of wildlife living in natural areas around the plant, and also protect natural conditions and restores biodiversity to sustain the natural resources for the local community.

Climate Change Management

The Company realized and placed importance on climate change, so it has prepared readiness to handle such challenges and determined to carry out the operations continually. Policies and operations on greenhouse gas have been comprehensively and clearly outlined.

In 2022, the Company has participated in the Climate Action Leading Organization (CALO) under Thailand Carbon Neutral Network (TCNN) and has announced its intention to become the carbon neutrality within 2050 to signify readiness of the Company on transformation to low carbon organization and to participate in driving the operation on reduction of greenhouse gas which are in line with the national policy with determination to be a role model on management of greenhouse gas emitted from the organization’s activity continually.

The Company has defined strategy, policy, work plan and goal on reduction of greenhouse gas emission including arranged campaigns to constantly participate in activities of the civil sectors and private sectors on reduction of impacts from intensified problems of greenhouse gas which have tendency to increase continually, through the following projects and activities:

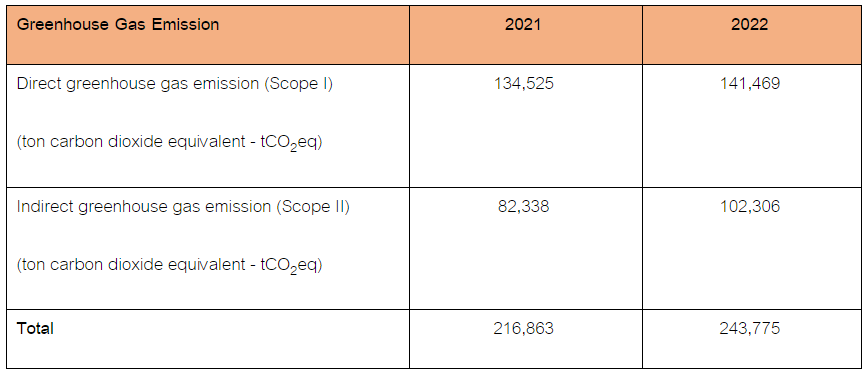

1.Greenhouse Gas Emission from the Organization

The Company monitored and managed greenhouse gas (GHG) emission from operations at corporate level continually. In 2022, the Company has been certified for Carbon Footprint for Organization from Thailand Greenhouse Gas Management Organization (Public Organization) (TGO). The Company’s calculation principle applied was based on the guidelines of ISO 14061-1 and the preparation of informatio on GHG emission has been verified by Lloyd’s Register (International) Thailand Limited, a greenhouse gas validation and verification body.

In 2022, total GHG emission from Scope I and Scope II was 243,775 tons carbon dioxide equivalent, an increase by 11% from 2021 due to the increased production capacity of 23%. The assessment on GHG emission also conformed to the certification on membership of Thailand Carbon Neutral Network (TCNN), in category of Climate Action Leading Organization (CALO) in Gold Level (Measurement).